In most cities around the world, the residents build their houses themselves, which as a consequence are often rickety. Nadia Remmerswaal invented a CNC milled formwork system that allows the cheap, rapid and safe construction of the main supporting structure. She intends to test it in an Indonesian kampong.

The components of her formwork system can be simply milled with a CNC milling machine from locally produced wood panels. "You slide the pieces of the puzzle together, tap in a wedge, and you are ready to pour in the concrete," explains Nadia Remmerswaal. All of the components are designed in such a way that they can be transported to the building site using a pushcart or wheelbarrow. It is possible to construct a four-storey building with this system. The geometry of the form is simple to adjust, allowing great flexibility in its design.

Remmerswaal, who graduated cum laude from the Faculty of Architecture and the Built Environment at TU Delft last year, wants to improve the possibilities for home-builders in developing countries with her CAST Formwork System (previously called the Tra-Digital Hybrid). After visiting Bandung (Indonesia), she became convinced that the apartment complexes planned by the government do not stand up to the chaotic neighbourhoods build by the residents themselves. "It is cosier here, people are happier, and given the varied set-up, there are more possibilities for small shops and offices. Architects often think that they know better what is good for the residents; my system gives them the possibility to build according to their own design – in a sound way.”

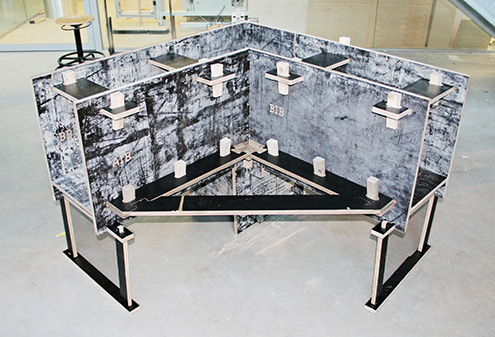

With subsidies from STW (€50,000), ASN Bank (€8,000) and 3TU Lighthouse (€50,000), she is now working to optimise the formwork system that was her graduation project. This is being done from her own company, CAST. The forms have been given a rounder shape – a milling machine is not good at creating right angles. And the flanges lie a bit further away from the locking point to make the form less fragile. Concrete plywood seems to be the ideal construction material for the moulds. The user can build a sturdy 'table construction' following a set method. First the columns (30 x 30) cm) and then the girders (30x30 cm). The storey height is 280 cm, the maximum span of the girders is 450 cm. These substantial dimensions make the building able to withstand the forces of nature, and, moreover, it is possible to add another floor on top later. Urban density thus becomes possible in the slums, instead of their usual endless expansion. Floors, walls, stairs and window frames can be constructed with traditional, local methods.

The theoretical market for this product is enormous. In Indonesia alone, around 80% of all houses are built by their residents. Nevertheless, Remmerswaal expects the marketing of the CAST system to be her greatest challenge. "This is new, and building higher than two low floors hasn't been done in the kampongs either. We have to show them that it is possible and convince people to use this system."

She has made agreements with local parties and government bodies to build six model houses in Bandung. How to convince people of the merit of this system on a large scale is still being researched. CAST may be introduced as a rental system in the local Indonesian construction market. Selling it to small local contractors is also an option.

Remmerswaal does not think it will be possible to introduce it as a home-building system to the Netherlands. "Unfortunately, it is too complicated to meet the Dutch building codes." The system will be implemented in Green Village on the TU Delft campus, though.